Frequently Asked Questions About Flange Protection

General

Depending on your application, we offer a variety of different flange protectors. Our flangeDOTS® are self adhesive and are simple to apply just by peeling the backing off and sticking to the equipment you want to protect. They stay put, unlike plastic push-in protectors. Our self adhesive protectors also have a VCI additive mixed into the adhesive, for added rust and corrosion protection. Our flangeBUMPERS® are a ridge form of flange protection that are easily attached with zip ties or multiNUTS. They are also weatherproof and highly UV resistant, which can’t be said for many of the other competitors. flangeBUMPERS® are extremely lightweight and do not require a lift when you are installing larger sizes.

- Apply a rust remover such as Cortec VpCI-423 to the flange face

- Allow the rust remover to penetrate for 1-2 minutes

- Using a soft bristle wire brush or Scotch Brite pad, scrub the flange face in the direction of the grooves (NEVER SCRUB ACROSS THE GOOVES).

- Wipe the flange face surface area with a towel as needed and re-apply Cortec VpCI-423. Continue to clean as necessary until the rust has been removed. *Process could take several applications if the flange face is severely rusted*

- One the flange face is clean, remove residual rust remover using Cortec VpCI-414 or Cortec VpCI-416.

- Wipe dry

- Apply VpCI-239, VpCI-422 or VpCI-423 by spray, brush, dip, or squeeze bottle. (VpCI-422 works well for large dip tank applications; VpCI-423 gel clings better to vertical surfaces that cannot be dipped.)

- Allow to sit for several minutes to one hour,* depending on severity of rust.

- Wipe off the rust and the rust remover, using a basic scrub pad or soft bristle brush for light abrasion if desired.

- Rinse with an alkaline cleaner solution such as VpCI-414, VpCI-416, or VpCI-418 LM (diluted up to 5% in water) to remove residue and provide flash rust protection.

- Repeat if needed.

A Upon inspection using PCC-1 inspection criteria, if the gasket sealing surface does not meet minimum criteria, PCC-2 allows for machining/resurfacing to bring the flange face sealing surface back to within acceptable criteria. Machining a flange removes a layer of metal from the flange and cuts a new surface profile (gramophone) back onto the surface of the flange.

Specialized refacing equipment is required to bring the raised face surface profile back to within ASME B16.5/B16.47 criteria. Refacing machines are OD/ID mounted onto the flange during the resurfacing process. Some of the more common refacing equipment suppliers are listed below

- E.H WACHS

- HYDRATIGHT

- MIRAGE MACHINES

- CLIMAX

P3- GIT stands for Gramophone Inspection Tool. This tool helps you identify weather or not your flange passes inspection. As you can see this one is used on an 8” flange with either a 150 or 300 lbs pressure class.

The cut-out window mimics where the gasket sealing surface will come in contact with the flange face. The cut-out area is the most critical area for inspection on the flange face. Any damage found in this area could result in possible re-facing. However, any damage on the flange face outside the window is acceptable and will pass inspection. The marks on the side of the GIT are in 10% percent increments that represent the gasket sealing surface. Refer to the asme PCC-1 table for heavy, moderate, and light damage percentages. We are using the P3GIT to show how a spiral wound gasket would sit on the flange face surface area.

Start by lining up the top of the GIT tool with the raised face of the flange. We are drawing where the gasket would sit on the face to see if the imperfections are on the critical surface area. Next, we are marking visible damage and using to tool to see if it is within the critical gasket sealing surface. If the damage does NOT fall inside the window, then the imperfection would pass inspection.

The two main causes of flange damage are associated with mechanical damage and pitting caused by corrosion.

Mechanical damage is caused when and object comes in direct contact with the flange sealing surface. Mechanical damage often occurs during lifting, transportation, flange alignment, and during the blast/paint process

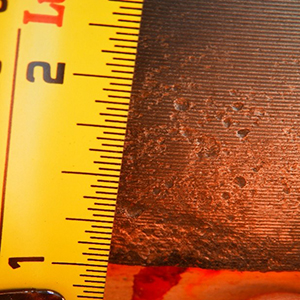

Pitting occurs due to excessive exposure to humidity/rain leaving cavities/holes in the surface of the flange face

A flange protector protects the flange face against corrosion and damage. At Precision Piping Products, we offer three different types of flange protectors.

- Self-Adhesive Flange Protectors: flangeDOTS+VCI and flangeDOT+Tag+VCI

- Peel and Stick

- Corrosion inhibitor embedded in the adhesive

- Leave no residue behind once removed

-Magnetic Flange Protectors: flangeMAGS and paddleMAGS

- Carbon Steel Applications only

- Magnetic backing

- PaddleMAGS come with handles to protect hand injuries

- Rigid Flange Protectors: flangeCORR, flangeBUMPER, flangeBUMPER+Gasket

- flangeCORR provides medium impact protection

- flangeBUMPERS provide a high resistance to impact protection for critical flanges

- flangeBUMPER+Gasket has a closed cell gasket attached to the back to provide a seal as well as high impact protection

A flangeBUMPER + Gasket provides the most robust protection in our line of products. A flangeBUMPER + Gasket protects the flange sealing surface with the attached closed cell foam gasket, while also providing the most robust impact protection. These are UV resistant and can be attached with zip ties, full sized bolts, or multiNUTS. We would suggest using a coat of Cortec VpCI-391 on the flange face before attaching the flangeBUMPER + Gasket.

Benefits of flangeBUMPER+Gasket:

- Keeps flange face protected

- Keeps pipe clean and dry

- Provides impact protection

- Easily connected and lightweight

- Reusable

- UV resistant

VCI stands for Volatile Corrosion Inhibitor. VCI’s are chemical substances that are applied to the surface area of metal that act as a barrier to inhibit/prevent corrosion from forming. VpCI stands for Vapor Phase Corrosion Inhibitor. Vapor phase Corrosion Inhibitors protect metal from corrosion without being in direct contact with the metal surface.

Product

flangeDOTS® are a flexible self-adhesive Flange Protector designed to protect the gasket surface area of a raised face flange during sand, bead and shot blasting and painting. They also keep the inside of the pipe spools, valves and vessels free of blast and paint debris during the blasting, painting and coating process. They can be used for long-term preservation but they must be paired with a flangeBUMPER or flangeBUMPER + Gasket to create a water tight seal.

We have tested flangeDOTS® with wind speed well over 100 MPH and find that our product will stay attached firmly. As long as the flange face is free of oils or dirt before applying a flangeDOT, it will stay on during shipping.

No, flangeDOTS® are designed as a peel and stick product. You just install it to a clean, dry surface and it’s ready for blast and paint.

Yes, flangeDOTS® are designed to be a peel and stick Adhesive Flange Protector with a proprietary pressure sensitive adhesive. You just remove the backer, align to the raised surface area of the flange and stick it. This will save countless hours in application time over conventional masking methods using layers and layers of tape and then trimming the tape to the raised surface area of the flange.

flangeDOTS® peel off with relative ease and leave no glue residue behind. Compared to traditional masking methods like duct tape that leave large amounts of glue and residue behind, costing you additional time and money to clean the flange surface, flangeDOTS® will speed up your process and put more money on your bottom line.

Our flangeBUMPERS® are a lightweight, weatherproof, composite flange protector that is capable of withstanding extreme impact forces. They rival the protection of blind flanges at a fraction of the weight and price. They can also be used for long-term preservation if paired with our flangeDOT.

flangeBUMPERS® are capable of withstanding well over 9200lbs of impact force without damaging the flange face.

Yes, we certainly can. We just ask that you meet our minimum order amount of $50 and an additional custom order fee will be added to your order. Contact us to find out more!

Our flangeBUMPERS® can be attached in multiple ways to achieve the same level of protection. Our multiNUTS™ are the ideal and most secure way of attaching them, but full-sized bolt/studs can be used, as can zip ties/cable ties.

flangeBUMPERS®+Gasket are a unique protector that we have developed that offers an extra layer of protection for the interior of a spool or equipment. While the flangeBUMPER® and flangeDOT® combined can hold pressure, the flangeBUMPERS®+Gasket are able to hold even higher pressures.

flangeDOTS®+Tags are an iteration of our flangeDOTS® that include an extended tag off one side that is intended to be exposed if the flange face is covered with a flangeBUMPER®. This ensures that the flangeDOT® will not be left on after assembly and is a visual verification that a flangeDOT® is present during storage.

flangeMAGS® are magnetic flange protectors that cover the raised face of a flange. They are ideal for keeping the raised face free of damage and keeping dirt and debris out of spools and equipment. They are most often used in areas where the flange cover may need to be removed and put back quickly, such as testing, welding, and fitting.

multiNUTS™ are a revolutionary method of attaching flange protectors to flanges. They are a patent-pending, tapered nut that fit in a variety of bolt holes and will accept a ¼”-20 machine screw. Because of these characteristics, they are highly versatile, and improve logistics. Our flangeBUMPERS® can be ordered to accommodate ¼”-20 machine screw, full sized bolts/studs, or both.

We also offer flangeRINGS™ which are made of the same material as our flangeDOTS®, but only cover the raised face of the flange. This allows the interiors of pipe spools, equipment, and manway covers to be accessible. You will need to specify the flange type, as the width can vary.

A groutDAM™ is a quick mold for sole plate grouting that allows sole plates to be grouted quickly and with significantly less labor than alternate methods. The groutDAM™ slips over the sole plate and is clamped down, then grout can be pumped in. Our groutDAM™ will work with epoxy-type and cement-type grout.

These two products are very similar, serve a similar function, and are constructed out of the same materials. They differ, however, in their sizes and application. The flangeBUMPERS®+Gasket are manufactured to B16.5 and B16.47 specifications, while the exhaustCOVERS™ are manufactured to the specifications of the exhaust flange for your application.

Our flangeDOTS® are safe for use on all materials. They have a water-based adhesive which does not contain any chlorides or carcinogens, and they do not leave residue.

paddleMAGS are designed to protect the gasket surface area of a raised face flange and keep the interior of pipe spools and vessels free from debris. Our paddleMAGS are excellent for weather mitigation and are easy to install and remove in seconds. The tabs on either side are a safety measure that ensure no one’s hands are going to get pinched. Our paddleMAGS are extremely lightweight and easy to store in a warehouse. They can also be continuously reused during in-process equipment alignments.

If a flangeDOT does not stick to the flange face, the most common issue would be a dirty flange face. Cleaning the flange face would be the first course of action. If a flangeDOT is placed over a rusted flange face, eventually the flangeDOT will begin to peel off. The flangeDOT will literally peel rust from the face and not adhere correctly. Another common cause is the flange face has residual oil from cleaning. If a product such as WD-40 is used to clean a flange face and a degreaser is not used to remove the residual product, the flangeDOT will not seal/stick correctly.

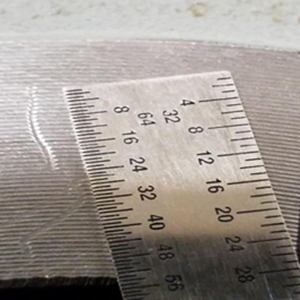

Long story short…clean the flange face. If your flange face looks like the one below, clean the flange face before applying a flangeDOT.

First, our pipeCOVERS will not crack or split like traditional pipe caps. P3 pipeCOVERS are UV rated and will last years in the most extreme outdoor conditions. Second, our pipeCOVERS take up less space because you can easily fold and stock them inside a warehouse. We can make them up to 120" and can customize them with your logo!

“P3” stands for Precision Piping Products.

“FD” is the product line, so FD in this case represents our flangeDOTS.

“035” is the thickness of the material in thousandths of an inch.

“04” is the size of the pipe.

“0” represents the fractional size of the pipe, for example a 1 ¼” pipe has a 1, a 1 ½” pipe has a 2, and a 1 ¾” pipe has a 3.

To put it plain and simple, NO.

flangeDOTS are not designed to be used for long-term preservation on their own. Our self-adhesive protector is excellent for short-term applications such as blasting, painting, shipping, and short-term storage.

In order for flangeDOTS to be used for long-term preservation they MUST be combined with our flangeBUMPER or flangeBUMPER+Gasket . This system is known as our Patented Preservation System that prevents corrosion of the flange face, keep debris out of your assets, and provides rigid impact protection.

Damage-Prevention

Preserving flanges is a multi-step process

- Clean the flange face using Cortec VpCI-423

- Remove residual Cortec VpCI-423 using Cortec VpCI-414 or 416

- Inspect the flange face for damage using PCC-1

- Apply a flangeDOT+VCI (warehouse/laydown) or a flangeDOT+Tag+VCI (work front)

- Attach a flangeBUMPER using multi-NUTS, bolts, or zip ties

Keep the flange covered using a flangeDOT+VCI or a flangeDOT+Tag+VCI. A proprietary VCI (Volatile Corrosion Inhibitor) is embedded in the adhesive of both flangeDOTS and flangeDOTS+Tag. The corrosion inhibitor embedded in the glue is both a contact and vapor corrosion inhibitor.

A flange face will need corrosion protection (especially on carbon steel flanges). flangeDOTS+VCI will cover the flange face while providing a corrosion inhibitor embedded in the adhesive. If a “stand alone” corrosion inhibitor is required, Cortec VpCI-391 is great for long term indoor/outdoor use. A rigid protector is also required impact protection. flangeCORR attached with multi-NUTS/Bolts/Zip Ties provides medium impact protection while a flangeBUMPER attached with multi-NUTS/Bolts/Zip ties provides high impact protection.

Storage flanges indoor when possible. If indoor storage is not available, ensure flanges are stored on dunnage 4-6” above the ground. Apply a flangeDOT+VCI or a flangeMAG during the welding process to ensure your flange is not damaged during fabrication. Complete all flange connections (fully torqued/tensioned) within 72 hours of flange makeup…DO NOT LOOSE BOLT FLANGES.

We offer products for a variety of different application such as...

- Corrosion Protection

- Impact Protection

- Shipping Protection

- Storage conditions/dunnage height Protection

- Welding Protection

Keep openings closed…upon arrival at the warehouse and laydown area, at the construction staging area, during installation, during pneumatic/hydrostatic testing, and during restoration. Implement a project specific “Build it Clean” protocols/procedures. Audit your cleanliness process on a regular basis. Hold people accountable when processes/procedures are not followed. Quality and safety go hand in hand…”right the first time” prevents re-work. Re-work/doing a task again due to poor quality, puts people are risk…RE-WORK=RISK.

You can easily prevent flange damage with our lightweight, UV resistant, rigid flangeBUMPER. These provide heavy inpact protection and can be attached with full size bolts, zip-ties, or multiNUTS and screws.

Impact protection is key to not damaging flanged spools and equipment connections during installation. flangeBUMPER/flangeBUMPER+Gasket provide the most effective lightweight impact protection. Shipping blinds are heavy, and once equipment is in place, damage often occurs when attempting to remove shipping blinds. Shipping blinds rarely come with lifting lugs. flangeBUMPER/flangeBUMPER+Gasket are easily removed and do not require rigging or lifting lugs during the removal process. Speaking of rigging…do not use flange bolt holts to lift spools. Using the bolt holes to lift spools causes damage to the sealing surface of the flange face.

PER ASME PCC-1 2013: Damage to the gasket sealing surface of a flange the penetrates both the flange face serrations depth and width. Flange damage is easily measured with our P3 Gramophone Inspection Tool (GIT). The video below explain how to properly identify damages on your flanges.

|

Flange Imperfection Classification |

Imperfection Depth/Serration Condition |

Maximum Imperfection Radial Dimension |

Imperfection Depth Hard-Faced Gaskets |

Imperfection Depth Soft-Faced Gaskets |

|

|

Heavy |

Below Flange Serrations |

25% of w |

Rd<w/4 |

<0.030 in. |

<0.050 in. |

|

Moderate |

At the bottom of Flange Serrations |

50% of w |

w/4<rd<w/2 |

<0.010 in. |

<0.030 in. |

|

Light |

Flange Serrations Remain Visible |

75% of w |

3/2<rd<3w/4 |

Not Allowed |

<0.005 in. |

What is FME?

FME is the process of preventing outside debris from entering critical areas such as equipment, machinery, or systems. Any object or material that enters a critical area and does not contribute to its purpose is considered outside debris. This debris could range from a variety of different materials such as tools, parts, dust, liquids, chemicals, etc.

How do I implement FME measures and products?

To establish effective FME measures your organization should consider the following key steps:

- Conduct a thorough risk assessment to identify frequent or potential areas of concern (critical systems and fluid codes).

- Develop clear FME procedures that align with your team and industry best practices.

- Provide comprehensive training to employees on FME protocols and guidelines.

- Regularly inspect FME practices to ensure compliance and effectiveness.

There are a wide variety of products on the market to help prevent contamination, protect your equipment and uphold FME policies and procedures. These products include:

- flangeDOT – A self-adhesive protector

- flangeBUMPER – A rigid protector

- flangeBUMPER+Gasket – A rigid protector that provides a watertight seal

- paddleMAG – A magnetic protector with safety handles

- pipeCOVER – A pipe protector that easily folds down

What is FOD?

Foreign Object Debris (FOD) refers to any foreign material or object present in a piping system. The term FOD is commonly used in a variety of industries such as aviation, aerospace, military, etc. FOD comes in various forms such as bolts, welding slag, grinding dust, wildlife, etc. Any foreign object present in a piping system can pose a serious risk to the piping systems, equipment, and crew if not properly managed.

Common Reasons for FOD

Understanding the sources of FOD is crucial for creating and implementing effective prevention measures. Some common sources of FOD include:

- Human Error: Improper handling of tools and equipment due to inattention to detail or lack of training.

- Weather Conditions: Intense winds, rain and other natural disasters can cause various debris.

- Improper Preservation: Material such as plywood, masking tape, tarp, plastic, etc. break down and does not keep out debris during storage.

- Wildlife Intrusion: Birds, small rodents, marine life, etc. entering operational areas.

How to Manage FOD

To mitigate the risk associated with FOD, companies should implement preventative measures such as routine inspections of the facility, equipment, and operational areas to identify and remove any hazards. It is also crucial to provide training to employees on FOD awareness and reporting procedures using toolbox talks, daily safety meetings, online training courses, etc.

To protect your equipment from FOD there are a wide range of products that make the process simple and effective. Products such as adhesive and magnetic flange protectors, as well as mechanical protectors for ridge protection and long-term preservation.

Applications

You are going to need a drill or screwdriver, a batROLL, for this size of flange small & medium multiNUTS, and a flangeBUMPER. This is what hydro jetting looks like without a flangeBUMPER on. This is a major safety hazard!

Typically, during hydro jetting like this you are required to rope off a 15ft exclusion zone in all directions. Meaning no one is allowed to work within this 15ft radius for safety. Now we are going to apply our flangeBUMPER and shrink that 15ft exclusion zone to only 3ft! We are attaching the medium multiNUTS backwards to ensure that nothing touches the flange face. Then we will secure the flangeBUMPER onto the pipe spool with our small multiNUTS facing the correct way, with the smallest part of the multiNUTS facing the bolt hole.

Finally, we are going to mask off the top of the flange bumper with a piece of bat tape. Make sure that you do not wrap it all the way around, you want an opening at the bottom so that the water can fall out. Now, check out the different our flangeBUMPER makes! We will finish it off by drying the pipe with an air compressor to ensure that no water is left inside. And now the inside of our pipe is nice and clean.

You are going to need a drill or screwdriver, a batROLL, for this size of flange small & medium multiNUTS, and a flangeBUMPER. Here we have our mock pipe spool and a bucket to catch the debris. As you can see the inside of our pipe is dirty, so we are going to blow it out with air.

This is our first attempt without the flangeBUMPER. All the debris missed the bucket and shot straight out. This serves as a major safety hazard and typically during velocity blows like this you are required to rope off a 15ft exclusion zone in all directions. Meaning no one is allowed to work within this 15ft radius for safety. Now we are going to apply our flangeBUMPER and shrink that 15ft exclusion zone to only 3ft!

We are attaching the medium multiNUTS backwards to ensure that nothing touches the flange face. Then we will secure the flangeBUMPER onto the pipe spool with our small multiNUTS facing the correct way, with the smallest part of the multiNUTS facing the bolt hole.

Finally, we mask off the top of the flangeBUMPER with a piece of batROLL. Make sure that do NOT wrap the batROLL all the way around. You want an opening at the bottom for the debris to fall out off. And now your pipe spool is ready for a velocity blow!

A flangeDOT is the best way to protect a flange during the blast and paint process. flangeDOTS are cut to ANSI pipe sizes and trimming/masking is not required. flangeDOTS are peel and stick taking only seconds to apply. Traditionally masking tape is cut to cover the flange face during the blast and paint process. The masking process takes time and mistakes are often made. Cutting a rectangular piece of tape into a circle with a sharp instrument is not a good idea for both your fingers and the flange face. Keep in mind, the chlorides in the glue of most masking tapes can damage stainless steel and exotic material flanges. The adhesive in flangeDOTS does not contain chlorides and is safe for applications on carbon steel, stainless-steel, P-91, and P-11 materials.

Our paddleMAGS are a simple and effective solution to protect your flanges in the rain. That are a magntic form of flange protection and have safety handles for easy installation & removal.

When stacking flanges you want nothing coming in contact with the flange face. The proper way to stack them is with the flange face pointing down, with wood raised it off of the floor. You can also use our flangeDOTS to protect your flanges when stacking them and the flangeDOT would prevent corrosion.

Short-Term Preservation

Tools: flangeDOT, batROLLS, flangeMAG, paddleMAG

- Typically short-term preservation lasts for 2-3 months.

- Our tool that were created for short-term preservation provide light impact protection and have VCI in the adhesive to prevent corrosion.

- These tools work best during blasting, painting, and fabriction applications.

Medium-Term Preservation

Tools: flangeRINGS, flangeCORR, mockGASKET

- Typically medium-term preservation lasts for 12 months.

- Our tools we created for this provide medium impact protection and keep the pipe interior clean.

- These tools work best for weather mitigation, shipping, staging, and testing.

Long-Term Preservation

Tools: flangeBUMPER, flangePORTHOLE, flangeBUMPER+Gasket, pipeCOVER

- Typically long-term preservation lasts for 24 months or longer.

- Our tools we created for this application provide rigid impact protection and keep the pipe interior clean.

- These tools work best for long-term storage in a warehouse or laydown yard, and protection your assets in harsh weather conditions.

In order to properly preserve a valve, we are using a Cortec VpCI- 101 emitter, and we stick it to the back of our flangeDOT, doing this will ensure that the emitter will not interfere with the valve seat.

To protect this for medium-term preservation you would need to attach a flangeCORR on top of the dot. You just align the flange CORR with the bolt holes on the valve and use multiNUTS and screws to secure it flush to the flange face. This system would provide preservation for up to 12 months.

Now to protect this valve for long-term preservation would need to attach a flangeBUMPER on top of the dot. This offers more ridged impact protection and will provide preservation for up to 24 months and over. You attached the flangeBUMPER in the same way, align it with the bolt holes on the ball valve and attached it with multiNUTS and screws.